In the intricate realm of fluid and gas systems, the choice of materials plays a pivotal role in ensuring optimal performance and longevity. Among the plethora of materials available, Nickel Alloy Instrumentation Tube Fittings stand out as a symbol of durability, corrosion resistance, and precision engineering. In this exploration, we delve into the exceptional attributes of Nickel Alloy Instrumentation Tube Fittings, examining their applications, advantages, and the unmatched quality they bring to diverse industries.

Understanding Nickel Alloy Instrumentation Tube Fittings:

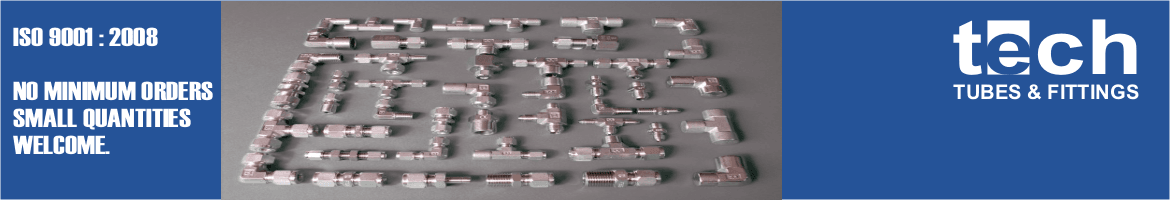

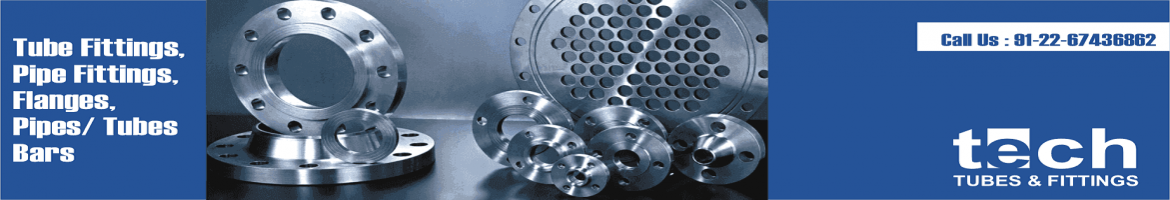

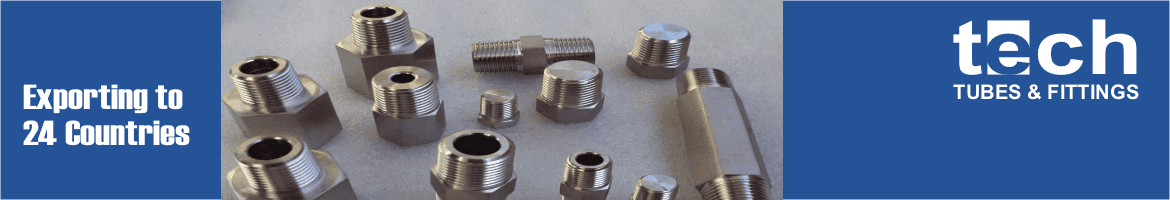

Nickel Alloy Instrumentation Tube Fittings are meticulously crafted components designed to facilitate secure connections within fluid and gas systems. These fittings are engineered using high-quality nickel alloys, which are known for their outstanding corrosion resistance, high temperature tolerance, and strength. The amalgamation of these properties makes Nickel Alloy Instrumentation Tube Fittings a preferred choice in industries where reliability is paramount.

Key Features and Advantages:

- Corrosion Resistance: Nickel alloys, including alloys such as Inconel and Monel, exhibit exceptional resistance to corrosion in harsh and corrosive environments. This makes Nickel Alloy Instrumentation Tube Fittings ideal for applications in chemical processing plants, offshore platforms, and marine industries.

- High Temperature Performance: Nickel alloys maintain their structural integrity and mechanical properties even at elevated temperatures. This characteristic makes Nickel Alloy Instrumentation Tube Fittings suitable for applications in high-temperature environments such as petrochemical refineries and power plants.

- Mechanical Strength: The inherent strength of nickel alloys contributes to the durability and longevity of Nickel Alloy Instrumentation Tube Fittings. They can withstand high-pressure conditions, making them crucial components in oil and gas pipelines and hydraulic systems.

- Versatility: Nickel Alloy Instrumentation Tube Fittings are available in various configurations, including elbows, tees, unions, adapters, and more. This versatility allows for seamless integration into a wide range of fluid and gas systems, providing tailored solutions for different industries.

Applications of Nickel Alloy Instrumentation Tube Fittings:

- Oil and Gas Industry: Nickel Alloy Instrumentation Tube Fittings find extensive use in oil rigs, refineries, and pipelines where corrosion resistance and durability are paramount.

- Chemical Processing: Industries dealing with corrosive chemicals and aggressive substances rely on these fittings to maintain the integrity of their fluid systems.

- Power Generation: In power plants and energy facilities, Nickel Alloy Instrumentation Tube Fittings contribute to the efficiency and reliability of fluid and gas conveyance systems.

- Aerospace: The high temperature and corrosion-resistant properties of nickel alloys make these fittings valuable in aerospace applications, ensuring precision and reliability.

- Marine and Offshore: Nickel Alloy Instrumentation Tube Fittings play a vital role in maritime applications, including shipbuilding and offshore drilling, where exposure to saltwater and harsh weather conditions demands resilient materials.

SEO-Friendly Integration of Keywords:

The usage of Nickel Alloy Instrumentation Tube Fitting and Tube Fittings in this discourse is intentional, aligning with the SEO strategy. These keywords are strategically placed to enhance the content's visibility on search engines, ensuring that individuals seeking information on nickel alloy fittings find this comprehensive guide.

In conclusion, Nickel Alloy Instrumentation Tube Fittings exemplify a perfect blend of strength, corrosion resistance, and precision engineering. Their widespread applications in critical industries underscore their significance in maintaining fluid and gas systems' integrity. As technology advances, Nickel Alloy Instrumentation Tube Fittings continue to evolve, contributing to the efficiency and reliability of complex industrial processes.