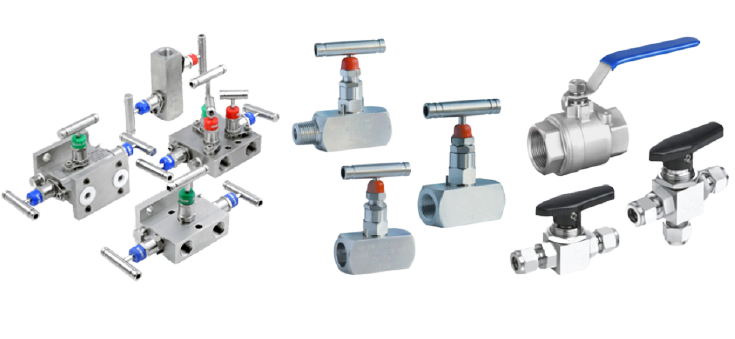

NEEDLE VALVES DEALER, STOCKIST, EXPORTER AND SUPPLIER IN INDIA

`

Isolation Needle Valves, High-Pressure Needle Valves Manufacturers in India, High-Temperature Needle Valve, SS Needle Valves, Duplex Steel Needle Valves, Carbon Steel Needle Valves, Double Ferrule Needle Valves, NPT Threaded Needle Valves, Double Bonnet Needle Valves, 10000PSI Needle Valves, 6000PSI Needle Valves, Needle Valve Exporter, and Manufacturer in Mumbai, India.

Tech Tubes & Fittings offers a wide range and nearly all types of bar stock and forged Needle Valves (Manufactures in India).

High pressure needle valve manufacturers in India available in threaded type and tube fitting end type in a wide range of sizes from 1/16”OD to 2”OD – 1mm OD to 50mm OD. It allows precise regulation of flow, although it's generally only atmospheric state High Pressure Needle Valve Manufactures in India we've a female end, screwed type needle Valve, Male Needle Valve, Female x Male thread needle Valve, Socket weld type needle Valve, Ferrule end needle Valve, Tube end needle valve, Union Bonnet type needle valve.

What is high Pressure Needle Valve?

High Pressure Needle Valve is additionally remarked as Isolation Needle Valve or Control Needle Valve sometimes will be a valve accustomed to regulate the flow of a substance – liquid or gas usually, through an appliance or system. The valve includes a tiny low plunger with a shape variety of a needle – this will be often a singular feature of a Needle Valve. a touch handle either Wheel type or Bar type is employed to enable easy, slow, and precise turning of the valve which successively helps to manage the flow to the Needle Valve from High to Low and so the opposite way around. When the elongated stem of the Needle Valve is fully tightened, it fits exactly into the seat to limit the flow of the medium (gas or liquid).

Tech Tubes & Fittings high pressure needle valve is manufactured in India and designed in such how that it requires multiple turns to open up completely or shut completely. It ensures that the valve both the ways either during opening or closing – parades or shuts smoothly and slowly. atmosphere Needle Valve prevents damage to gauges and other equipment which can be affected thanks to sudden bursts of gas or liquid. atmospheric state Needle Valve helps in better control and regulation.

These High Pressure Needle Valves are manufactured from a pressure range of 100 Bars – 1500PSI to 1000 Bars - 15000PSI.

Expertly Engineered High-Pressure Needle Valves at Tech Tubes & Fittings

Tech Tubes & Fittings is one of India's leading high pressure needle valve manufacturers, manufacturing bar stock and forged valves that are essential in efficiently managing the flow of gases and liquids in numerous systems.

Built to Last

Our range features various options, from isolation needle valves to those suited for high-pressure and high-temperature environments. These valves are crafted from robust materials such as stainless steel, duplex steel, and carbon steel and are built to last and perform exceptionally in any setting.

Versatile Application

Our collection encompasses a broad spectrum of specifications, suitable for pressures ranging from 100 Bars (1500PSI) to an impressive 1000 Bars (15000PSI), meeting the diverse requirements of different industries.

Innovative Design

The design of our needle valves is particularly noteworthy. They require multiple rotations to fully open or close, ensuring a controlled, gradual adjustment. This gradual operation is vital for avoiding sudden surges in gas or liquid flow, thereby safeguarding equipment and enabling precise flow regulation.

Precise Control

Tech Tubes & Fittings offers a variety of connection types for our needle valves, including threaded, tube fitting, and socket weld options. Available in sizes from 1/16”OD up to 2”OD, each valve features a meticulously crafted small plunger shaped like a needle coupled with a user-friendly handle. The design allows for exact flow control, underlining our commitment to delivering innovative and quality products.

We at Tech Tubes & Fittings recognize high-pressure needle valves are indispensable to various sectors. Our dedication to providing superior-quality products and expert guidance ensures optimal system performance. Whether you require standard models or customized solutions, our team is there to assist. Explore our comprehensive range and contact us today to discover how our high-pressure needle valves can elevate the efficiency and safety of your operations.

Needle Valve

Hydraulic Needle Valve

Hex Needle Valve

Male & Female Needle Valve

Needle Valve - Step by Step Complete Guide

HOW ARE HIGH PRESSURE NEEDLE VALVES MANUFACTURING?

High Pressure Needle Valve Manufacturing in India In various factors. Atmosphere High Pressure Needle Valve is employed under stress to carry larger amounts of gas and liquids. These gases and liquids may contain chemicals which is ready to cause damage to several materials and thus it's vital, finally most essential, to decide on highly durable. the foremost common choice for top Pressure Needle Valves is stainless-steel especially chrome steel 304 / 304L or chrome steel 316/316L. this kind of chrome steel is proof against chemical damage to some extent and also proves to be corrosion proof if the liquid or gas is compatible. This fashion maintenance costs remain low. Steel, Brass stands as a general choice for top Pressure Needle Valve. Not Only from stainless-steel, steel, and Brass, these atmosphere Needle Valves are manufactured in India, in various type of highly durable materials like Inconel, Duplex stainless-steel, Super Duplex steel, Monel, Hastelloy, Titanium, Nickel.

High Pressure Needle Valves must be used only reckoning on their compatibility with the medium. high Needle Valves should be able to withstand extreme temperatures. Often, the gases or liquids pushed through these Needle Valves are extremely hot or cold.

HOW DOES HIGH PRESSURE NEEDLE VALVE WORK?

High Pressure Needle Valves is operated manually or automatically. Our scope consists only of operated by hand Needle Valves. atmospheric state Needle Valves use a hand wheel or the identical arrangement to manage the space between the spindle tip and valve set. When the handle is turned in one position, it opens the valve and causes the liquid/gas to flow in. high Needle Valve and opposite action of closing the Needle Valve causes the shutting down of the flow of liquid or gas.

USES OF atmospheric state NEEDLE VALVE?

• Atmospheric state Needle Valves are commonly accustomed provide shut off for a guage.

• Atmosphere Needle Valves are used for shut off of the supply of Anhydrous Ammonia applications.

• High Needle Valves are generally not employed in simple shutoff applications like valve

• The orifice of atmospheric state needle valve is smaller and then the force advantage of the finely threaded stem is high.

• High Needle Valves are easy to shut off because of the fine thread stem even when the pressures are high.

• High Needle Valves are often tightened just by the fingers.

Specification of atmospheric state Needle Valves

• Inlet Connection Size:- 1/4″, 3/8″, 1/4 Npt, 3/8 Npt, 1/2 Npt, 6 Mm, 12 Mm

• Outlet Connection Size:- 1/4″, 3/8″, 1/4 Npt, 3/8 Npt, 1/2 Npt, 6 Mm, 12 Mm

• Materials Of Construction:- Stainless-steel, Monel, Duplex, Super Duplex, Hastelloy, Steel, 6mo, Titanium, Incoloy 825, Incoloy 625

• Maximum Operating Pressure :- 3000, 6000, 10000, 15000 Psi

• Flow Coefficient 1:- 35 Standard CV

• Minimum Operating Temperature:- -54 °C -65 °F

• Maximum Operating Temperature :- +538 °C +1000 °F

• Seat Material:- Metal/Metal

• Packing Material:- PTFE

• Mounting Option:- Base Mount

Cities

Visakhapattnam, Unnao, Indore, Surat, Pune, Chennai, Bhilai, Nagpur, Delhi, Faridabad, Chandigarh, Kanpur, Nashik, Coimbatore, Bangeluru, Jamshedpur, Vadodara, Jaipur, Udaipur, Bokaro, Pithampur, Noida, Ludhiana, Durgapur, Mysore, Moradabad, Aurangabad, Navi Mumbai, Thane, Kharagpur, Kolhapur, Ratnagiri, Belgaum, Rourkela, Panipat, Ichalkaranji, Ahmedabad, Hyderabad, Sri City, Hospet, Rudrapur, Raigarh, Aluva, Vijaywada, Firozabad, Belagavi, Bharuch, Thiruvananthpuram, Ankleshwar, Gajraula, Margao, Hosur, Gurugram, Pimpri, Chinchwad, Meerut, Morbi,

Barcelona, Chicago, Texas, Houston, Detroit, Osaka, Randstad, San Jose, Sao Paulo, Seoul, Singapore, Tokyo, Toronto, Al Jubail, Dubai, Sharjah, Abu Dhabi, Edmonton, Nevada, Rotterdam, Illinois, California, Cleveland, Moscow, Riyadh, Muscat, Bahrain, Leduc, Arlington, Tulsa, KAEC, Reno, Yanbu, Ontario, St. Lawrence Valley, Silesia, Kuzbass, Tartu, Ponferreda, Plovdiv, Asti, Atarfe, Istanbul, Los Angeles, Ho Chi Minh City, Bogota, Hanoi, Hong Kong, Montreal, Manama, Brisbane, Tehran, Baku, Kuala Lumpur, Rio de Janerio, Johannesburg, Mexico City, Milan, Ankara, Doha, Al Khobar, Ulsan, Jakarta, Santiago, Madrid, Dammam, Dhaka, Manila, Lima, Lagos, St Petersburg, Abidjan, Dar Es Salaam, Jeddah, Alexandria, Yokohama, Guayaquil, Algiers, Kano, Nairobi, Incheon, Brasilia, Salvador, Kiev, Buenos Aires, Rome, Taipei, Osaka, Chittagong, Daegu, Bursa, Accra, Guatamala, Bucharest, Cordoba, Melbourne, Sydney, Vienna, Ganja, Brussels, Sofia, Havana, Helsinki, Tbilisi, Hamburg, Athens, Debrecen, Dublin, Cork, Tel Aviv, Jerusalem, Ammam, Auckland, Oslo, Begen, Lisbon, Porto,

Durban, Cape Town, Stockholm, Gothenburg, Kampala, Kyiv, Birmingham,

exports

We have built strong relationships and exports all over the world in countries like

Denmark, Costa Rica, Croatia, Cuba, Ecuador, Egypt, Estonia, Fiji, Finland, Georgia, Germany, Ghana, United Kingdom (UK), Greece, Guatemala, Hungary, Iceland, Indonesia, Iran, Iraq, Italy, Israel, Japan, Jordan, Kazakhsthan, Kenya, Paraguay, Peru, Philippines, Poland, Portugal, Puerto Rico, Qatar, Romania, Russia, Saudi Arabia, Serbia, Singapore, Slovakia, South Africa, South Korea, Sudan, Spain, Sri Lanka, Sweden, Switzerland, Tajikistan, Tanzania, Thailand, Togo, Turkey, Turkmenistan, Uganda, Ukraine, United Arab Emirates (UAE), United States of America (USA), Uruguay, Uzbekistan, Venezuela, Vietnam, Yemen, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Liechtenstein, Lithuania, Macedonia, Malaysia, Maldives, Mali, Malta, Mauritius, Mexico, Moldova, Montenegro, Nepal, Netherlands, Nigeria, Norway, Oman, Afghanistan, Albania, Algeria, Argentina, Australia, Azerbaijan, Bahamas, Bahrain, Belarus, Belgium, Bolivia, Bosnia & Herzegovina, Brazil, Brunei, Bulgaria, Myanmar, Canada, Chile, Colombia, New Zealand, Nicaragua, Panama, Guyana, Suriname, French Guiana, Ireland, Austria, Kosovo, Slovenia, Andorra, Angola, Anguilla, Armenia, Aruba, Austria, Benin, Bolivia, Bosnia and Herzegovina, Burundi, Burkina Faso, Benin, chad, Cocos Island, Comoros, Colombia, Cuba, Cyprus, Croatia, Denmark, Dominica, Djibouti, Eritrea, Estonia, Ecuador, Finland, Fiji, Falkland Island, French Polynesia, Ghana, Gabon, The Gambia, Gibraltar, Guam, Grenada, Guyana, Guinea, Greenland, Haiti, Holy See, Honduras, Kosovo, Kyrgyzstan, Libya, Lesotho, Lithuania, Luxembourg, Latvia, Malawi, Mali, Malta, Macau, Madagascar, Maldives, Mayotte, Mauritius, Martinique, Monaco, Mongolia, Moldova, Mayotte, Mozambique, Morocco, Montserrat, Namibia, Nauru, Niger, Niue, Nigeria, Norway, Nicaragua, Northern Mariana Island, Palau.

LEGAL DISCLAIMER

|

All registered names, trademarks, copyrights and part numbers like Inconel, Monel, Hastelloy, Zeron etc., remain the property of their respective owners. All use of OEM names, part, model and item numbers are for reference and identification purposes only. TECH TUBES & FITTINGS is not an endorsed reseller or representative of any of above listed Materials / Brands or their respective products. TECH TUBES & FITTINGS products do not infringe on Trade Marks Act 1995 or Copyright Act 1968, and to the best of our knowledge and through investigation we are not in contravention of any current patents |