Needle valves are vital components used in various industries for precise flow control of fluids and gases. These valves feature a slender, tapered pin that can be gradually raised or lowered within the valve body to regulate the flow passage, allowing for precise adjustment of flow rates. Below, we…

How to choose a Duplex Steel Instrumentation Tube Fittings?

Selecting Duplex Steel Instrumentation Tube Fittings involves considering several critical factors to ensure they meet your system requirements. Here are steps to guide your selection process:

- Material Compatibility: Ensure Duplex Steel (a combination of austenitic and ferritic steel) aligns with your application needs. Consider its resistance to corrosion, high strength, and suitability for the specific fluids or gases in your system.

- Pressure and Temperature Ratings: Determine the maximum pressure and temperature your system operates under. Ensure the chosen fittings can withstand these conditions without compromising performance.

- Size and Configuration: Determine the fitting size and type required for your system. This includes configurations like elbows, tees, adapters, unions, or couplings. Ensure the fittings align with the tube sizes and connections needed in your setup.

- Leakage Prevention: Look for fittings that offer a secure and leak-free seal. Consider the design, quality of the ferrule, and the compression capability of the fitting to ensure a reliable seal.

- Standards and Certifications: Ensure the fittings meet industry standards and certifications for quality, such as ASTM, ASME, or ISO standards. Compliance with these standards ensures the fittings' reliability and performance.

- Application-Specific Requirements: Consider the unique demands of your application. Some applications, like those in aggressive environments or high-stress areas, may require specific Duplex Steel grades or surface finishes.

- Corrosion Resistance: Duplex Steel is known for its corrosion resistance. However, ensure it meets the specific corrosion resistance needs of your application, especially in environments with high chloride content or acidic conditions.

- Consultation with Experts: Seek advice from professionals or manufacturers specializing in Duplex Steel Instrumentation Tube Fittings. They can provide valuable insights and recommendations based on your system requirements.

- Performance Testing and Validation: Prioritize suppliers or manufacturers who offer performance testing and validation data for their fittings. This data helps ensure the fittings meet your system's demands and performance expectations.

- Cost Consideration: While quality is crucial, consider the overall cost of the fittings, including installation, maintenance, and potential long-term savings due to their durability and reliability.

By carefully evaluating these factors, you can make an informed decision when choosing Duplex Steel Instrumentation Tube Fittings that best suit your system's requirements, ensuring efficient and reliable fluid or gas conveyance

How to choose a Male Connector?

Choosing a male connector involves considering various factors such as the application, electrical specifications, physical characteristics, and environmental conditions. Here are some steps to guide you through the process:

- Identify the Application:

- Determine the purpose of the connector. Is it for power transmission, data transfer, audio/video signals, or something else?

- Electrical Requirements:

- Consider the electrical specifications, such as voltage, current, and frequency. Make sure the connector can handle the specific requirements of your application.

- Connector Type:

- There are various types of connectors, such as USB, HDMI, Ethernet, audio jacks, etc. Choose the type that matches your specific needs.

- Connector Size and Shape:

- Consider the physical size and shape of the connector. Ensure it fits within the available space and is compatible with the mating connector.

- Termination Method:

- Connectors can have different termination methods, including soldering, crimping, or screw terminals. Choose the one that suits your installation preferences and requirements.

- Environmental Conditions:

- Consider the environmental conditions in which the connector will be used. Factors such as temperature, humidity, and exposure to chemicals can affect the choice of materials and the type of connector.

- Mating Compatibility:

- Ensure that the male connector is compatible with the female connector on the other end of the connection. Check for industry standards to ensure interoperability.

- Durability and Reliability:

- Evaluate the connector's durability and reliability, especially if it will be subjected to frequent insertions and removals. Look for connectors with robust construction and materials.

- Shielding and Insulation:

- If your application requires protection against electromagnetic interference (EMI) or environmental factors, choose connectors with appropriate shielding and insulation.

- Standards and Certifications:

- Check if the connector complies with industry standards and certifications. This ensures that it meets certain quality and safety criteria.

- Cost Considerations:

- Consider your budget constraints, but keep in mind that choosing a connector solely based on cost may lead to compromises in performance and reliability.

- Consultation and Research:

- If you're unsure about the best connector for your application, consult with experts in the field or do thorough research to gather information about available options.

Remember that the selection process may vary depending on the specific requirements of your project, so take the time to carefully evaluate your needs before making a decision

Blog Posts

Needle Valves

Needle Valves

Needle valves stand as indispensable components in fluid control systems, providing precise regulation of flow rates and pressures across various industrial applications. Paired with tube fittings, they form a critical part of fluid handling mechanisms, ensuring accuracy and r…

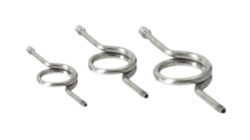

Important Points to consider while purchasing Ferrule Fittings

Single Ferrule Tube Fittings or Double Ferrule Tube Fittings are available in several makes and standards

around the globe. These fittings are used for extremely critical applications. These come in various pressure

ranges, moc, sizes and grades.

The base of the use of the fitting is to hold …

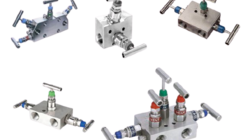

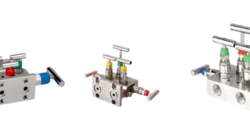

Manifold Valve- Uses, Types, Industries

To get the best manifold valve from the best manufacturer and supplier Techtube, let's take a look at its type and use. Let's get started.

Uses of Manifold Valves

Depending on the need, manifolds are employed in my various fluid power applications. Manifolds can be used to mount valves or to…

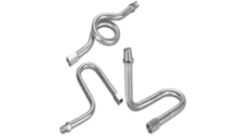

Features and Application of Tube Fittings

Features and Application of Tube Fittings

In pipe systems, a fitting or adapter is used to join straight sections of pipe or tube, adapt to varied sizes or forms, and regulate fluid flow, among other things. In a domestic or business context, these fittings are used to control the flow of water, gas, or liquid waste through a series of pipes or tubes. One of the fundamental differences between the tube and the pipe is that the tube is never threaded at the end to provide a connection. Instead, a tube fitting is required to join two tubes, a pipe to a pipe, or a piece of equipment to a piece of hardware (such as an instrument).

Applications of Tube Fittings

When it comes to optimizing component selection, visiting a fitting supplier is usually a smart idea because the structure and material requirements of fittings are application-specific. Tube fittings, on the other hand, are most commonly used with hydraulic or pneumatic systems. The first step in choosing the sort of fittings that are appropriate for the application is to identify the core system type.

Hydraulic applications include the transportation of liquid fluids such as water and other chemical solvents. Hydraulic fittings must have liquid-tight seals and are typically resistant to rust and other chemical damage.

Gas transportation is engaged in pneumatic applications. Pneumatic fittings must have exceptionally tight seals and be chemically resistant to avoid gas loss.

Tube fittings are used in several different applications, including structural design. Because these fittings do not transmit fluids, they must have excellent physical integrity but do not need to seal.

Features of Tube Fittings

- Rather than nominal specs, tubes and their fittings are frequently given by precise dimensions.

- Tubes are also commonly employed in structural applications where the outside diameter is the size criterion (OD). Pipes are most typically used as fluid transfer vessels, with the internal diameter serving as the size criterion (ID).

- The most basic component of tube fittings, proper sizing, can be addressed.

- The most important operating criteria for fitting tubes are pressure and temperature.

- Tube fittings are typically selected in tandem with tube materials.

- The decision is influenced by factors such as cost, flexibility, media, environmental conditions, and the required pressure ratings. As choices, various types of plastic and metal are available.

Needle Valve - Step by Step Complete Guide

Needle Valves: Uses, Types, Industries

Needle valves are vital components used in various industries for precise flow control of fluids and gases. These valves feature a slender, tapered pin that can be gradually raised or lowered within the valve body to regulate the flow passage, allowing for precise adjustment of flow rates. Below, we…

Tech Tubes & Fitting's Blog

Needle Valves: Uses, Types, Industries

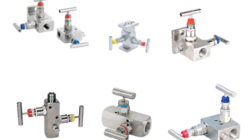

Needle valves are vital components used in various industries for precise flow control of fluids and gases. These valves feature a slender, tapered pin that can be gradually raised or lowered within the valve body to regulate the flow passage, allowing for precise adjustment of flow rates. Below, we explore the uses, types, industries, and their relevance to tube fittings.

Uses of Needle Valves:

- Flow Control: Needle valves are primarily used for precise flow control applications where accurate regulation of fluid or gas flow is required.

- Pressure Regulation: They are also utilized for pressure regulation tasks, ensuring that pressure levels remain within specified limits.

- Shut-Off Applications: Needle valves can act as shut-off valves to stop the flow completely when necessary, providing reliable sealing and preventing leakage.

- Instrumentation: In instrumentation systems, needle valves are employed for fine-tuning flow rates in sensitive equipment such as pressure gauges and flow meters.

Types of Needle Valves:

- Straight Needle Valves: These valves have a straight flow path and are suitable for general-purpose applications.

- Angle Needle Valves: Featuring an angled flow path, these valves are ideal for installations where space constraints exist or where flow direction needs adjustment.

- Integral Bonnet Needle Valves: These valves have the bonnet integrated into the valve body, enhancing durability and minimizing potential leak paths.

- Threaded Needle Valves: Threaded needle valves have threaded connections for easy installation and removal, making them suitable for temporary or low-pressure applications.

Industries Utilizing Needle Valves:

- Oil and Gas: Needle valves are widely used in oil and gas production facilities, refineries, and pipelines for flow and pressure control in process lines and sampling systems.

- Chemical Processing: In chemical plants, needle valves play a critical role in controlling the flow of corrosive and hazardous chemicals with precision.

- Power Generation: Power plants utilize needle valves in steam and water systems for flow control, pressure regulation, and isolation of equipment.

- Aerospace: Needle valves are employed in aerospace applications for regulating fuel flow, hydraulic fluid, and pneumatic systems in aircraft and spacecraft.

- Instrumentation and Laboratory: These valves are essential in instrumentation systems, analytical equipment, and laboratories for precise flow and pressure control in experiments and testing.

Relevance to Tube Fittings: Needle valves are often integrated into tube fitting assemblies to provide flow control capabilities. They can be connected to tubing using compression fittings, flare fittings, or other tube fitting types. By incorporating needle valves into tube fitting systems, engineers can achieve precise flow control and isolation in fluid handling systems.

In conclusion, needle valves are versatile components with diverse applications across various industries. Their ability to provide precise flow control, pressure regulation, and shut-off capabilities makes them indispensable in critical processes. When integrated with tube fittings, needle valves enhance the functionality and performance of fluid handling systems, ensuring efficient operation and reliability

Needle Valves

Needle Valves

Needle valves stand as indispensable components in fluid control systems, providing precise regulation of flow rates and pressures across various industrial applications. Paired with tube fittings, they form a critical part of fluid handling mechanisms, ensuring accuracy and reliability in diverse environments. This exploration delves into the significance of needle valves in tandem with tube fittings, shedding light on their functionality, applications, and transformative impact in fluid control systems.

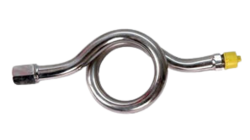

Understanding Needle Valves and Tube Fittings:

Needle valves are characterized by a slender, tapered stem and a threaded plunger, which allow for fine adjustments to flow rates. When paired with tube fittings, such as compression fittings or push-to-connect fittings, needle valves facilitate the seamless integration of fluid control mechanisms into piping systems. This combination ensures tight seals and precise control over fluid flow, making it ideal for applications where accuracy is paramount.

Key Features and Advantages:

- Precise Flow Control: The tapered stem of needle valves enables precise adjustments to flow rates, allowing for fine-tuning of fluid flow within the system. This level of control is essential in applications where even minor variations in flow can impact performance or safety.

- Leak Prevention: Needle valves, when coupled with tube fittings, create tight seals, minimizing the risk of leaks or fluid loss. This ensures the integrity of the fluid control system, reducing maintenance requirements and enhancing overall reliability.

- High Pressure Capability: Needle valves are designed to withstand high-pressure environments, making them suitable for applications where fluid systems operate under significant pressures. When paired with robust tube fittings, they offer a dependable solution for controlling fluids in demanding conditions.

- Versatility: Needle valves can be used in a wide range of industries and applications, thanks to their versatility and adaptability. Whether in industrial manufacturing, chemical processing, or laboratory settings, needle valves paired with tube fittings provide reliable fluid control solutions.

- Compact Design: Needle valves are typically compact in design, making them suitable for installations where space is limited. When coupled with streamlined tube fittings, they offer a space-efficient solution without compromising performance.

Applications of Needle Valves and Tube Fittings:

- Process Control Systems: Needle valves paired with tube fittings are commonly used in process control systems, where precise regulation of fluid flow is essential. They enable operators to adjust flow rates with precision, ensuring optimal performance of industrial processes.

- Laboratory Equipment: In laboratory settings, needle valves and tube fittings play a crucial role in controlling the flow of gases and liquids in analytical instruments and experimental setups. Their precision and reliability contribute to the accuracy of laboratory measurements and experiments.

- Hydraulic Systems: Needle valves are integral components of hydraulic systems, where they regulate the flow of hydraulic fluids. Paired with tube fittings, they provide a dependable solution for controlling fluid pressures and ensuring smooth operation of hydraulic machinery.

- Chemical and Petrochemical Industries: Needle valves and tube fittings find extensive use in the chemical and petrochemical industries, where they control the flow of corrosive fluids and gases. Their ability to withstand harsh chemical environments makes them indispensable in these applications.

- Oil and Gas Production: In oil and gas production facilities, needle valves and tube fittings are employed in wellhead control systems, flow control valves, and instrumentation panels. Their reliability and precision contribute to the safe and efficient operation of oil and gas extraction processes.

Challenges Addressed by Needle Valves and Tube Fittings:

- Cavitation and Erosion: In high-pressure fluid systems, needle valves may experience cavitation or erosion due to the rapid changes in fluid velocity. Proper selection of materials and regular maintenance help mitigate these challenges, ensuring the longevity of the valves and fittings.

- Temperature Extremes: Needle valves and tube fittings may be subjected to extreme temperatures, which can affect their performance and integrity. Choosing materials with high temperature resistance and implementing thermal insulation measures help address this challenge, ensuring the reliability of the fluid control system.

In conclusion, needle valves paired with tube fittings form a dynamic duo in fluid control systems, offering precise regulation, leak prevention, and high-pressure capability across various industries. Their versatility and reliability make them indispensable components in applications where accuracy and efficiency are paramount. As industries continue to evolve, needle valves and tube fittings will remain at the forefront of fluid control technology, driving innovation and excellence in fluid handling mechanisms.

Top of Form

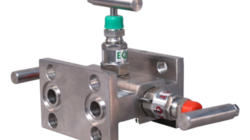

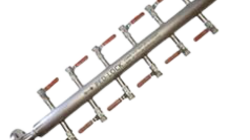

How to choose a 2 Way Manifold Valve?

Have a 2 way manifold valve from Techtube but before that receive some insight and data viewing it. Let's go.

What is a 2 way manifold valve?

A two way manifold valve keeps the capsule's span from being outdone. It is also feasible to separate the transmitter from the technique circle. This system consists of two block valves, a high-pressure piece valve, and a low-pressure piece valve.

Shutting down the block valve and unlocking the drain valve is the method for measuring pressure on a pressure transmitter. You'll need to connect the drain valve to a pressure generator to test the pressure after you've cleared it. A two way manifold valve is also known as a block and bleed valve.

Things to be remembered while choosing a 2 way manifold valve

Everything needs to be checked before placing the order. Likewise, you can have the below-stated points while having your 2 way manifold valve. Let's begin.

1. Material

Metal or plastic can be used to make a two-way manifold valve. However, because the resistivity of various materials varies, it's vital to know everything there is to know about the material in your two-way manifold. This will aid in the escape of any damage while fluids or gases are being distributed.

2. Port size

For the management valves and fittings required for an application, manifold valves provide a combination of intake and outcome refuge options. To speed up induction in the collector's production refuges, pick parts with similar thread diameters while creating your fluid control path.

3. Number of Stations

2 way Manifold valves are being recommended from two to ten stations for the collectors. But, you can operate the stations up to a certain limit only when assigned.

4. Spacing

2 way Manifold valves should contain an accurate spacing between their reaction ports. This will help maintain your fluid and gas release operation operating smoothly. There should be no clashing or summit of your aspects with other units.

5. Operating Pressure

The operating pressure of a two-way manifold valve is determined by the material used in it. The working pressure of your 2 way manifold valve should be determined by the manufacturer who is creating your 2 way manifold valve for you.

6. Placement

When building a two-way manifold, you need to think about both the economical and physical aspects. As a collector or producer, you must work smartly and efficiently with limited resources rather than wastefully extending your resources

For More Details on How to choose a 2 Way Manifold Valve contact us on sales1@techtubes.in

***Monel, Hastelloy, Inconel, Incoloy, SMO254, Nitronic, AL6XN, Stellite, Sanicro, Tantalum, Nimonic , Alloy A286, Invar, Cupronickel etc., are the trademarks of their respective companies.Important Points to consider while purchasing Ferrule Fittings

Single Ferrule Tube Fittings or Double Ferrule Tube Fittings are available in several makes and standards

around the globe. These fittings are used for extremely critical applications. These come in various pressure

ranges, moc, sizes and grades.

The base of the use of the fitting is to hold the Tube in such an extremely firm manner to cause zero friction

zero leakage. The buyer 'must' consider these points prior to buying the products.

- The eligibility of the Single Ferrule Tube Fittings or Double Ferrule Tube Fittings should be considered while assembling it with a thin wall tube or thick wall tube. This shall ensure that the pipe is not affected.

- The most critical criteria of buying single compression fittings / double compression fittings is corrosion. Buyer must check and ensure that the fittings are free from any kind of rust or contamination. The single compression fittings / double compression fittings that are not rust free may weaken the entire structure.

- The single ferrule fittings / double ferrule fittings must be free of contamination. For highly critical services like Oxygen Service, it is very important to install contamination free and rust free fittings.

- For longer life and lesser maintenance of these products it is very important to choose the right Grade.

- The fittings should take less time and labor to install. Moreover the biting of the ferrule should be easy and hassle free.

- Ferrule is the heart of the fittings. Basically there are 3 part of the fittings, namely The Body, The Nut and The Ferrule(s). Out of these the ferrule is most important part which is the major reason of keeping the tube intact with the fitting. Thus causing no leakage.

- The ferrule should be heat treated as per requirements.

Single Ferrule Fittings and Double Ferrule Fittings are available in markets. However, it is extremely important to identify the quality of fittings, the dimensions and minimum required length of threads, the quality of ferrule especially. It is essential to buy it from a genuine manufacturer which will help the buyer to retain the strength of the entire structure.

For More Details on Important Points to consider while purchasing Ferrule Fittings contact us on sales1@techtubes.in

***Monel, Hastelloy, Inconel, Incoloy, SMO254, Nitronic, AL6XN, Stellite, Sanicro, Tantalum, Nimonic , Alloy A286, Invar, Cupronickel etc., are the trademarks of their respective companies.